Pro Press Tool Maintenance Tips – Keep Your Tool Working Like New

A pro press tool is one of the most valuable investments for plumbers and HVAC professionals.

But like any precision tool, it needs regular maintenance to keep it performing at its best.

Neglecting basic care can lead to inconsistent presses, leaks, or even tool failure – which could cost you time and money on a job.

In this guide, you’ll learn how to maintain your pro press tool, how often to calibrate it, and what habits keep it in top condition for years.

💡 Related: Not sure which model you’re using? Check out our comparison – Best Pro Press Tools for 2025 – Reviews, Comparison & Buying Guide

🔧 Why Maintenance Matters

Every time you press a fitting, your tool experiences mechanical stress. Over time, that wear affects jaw alignment, hydraulic pressure, and pressing accuracy.

Proper maintenance ensures:

- Consistent, leak-free joints

- Longer tool lifespan

- Better jobsite reliability

- Fewer calibration issues

Whether you own a Ridgid, Milwaukee, or Viega press tool, regular maintenance is key to reliable performance.

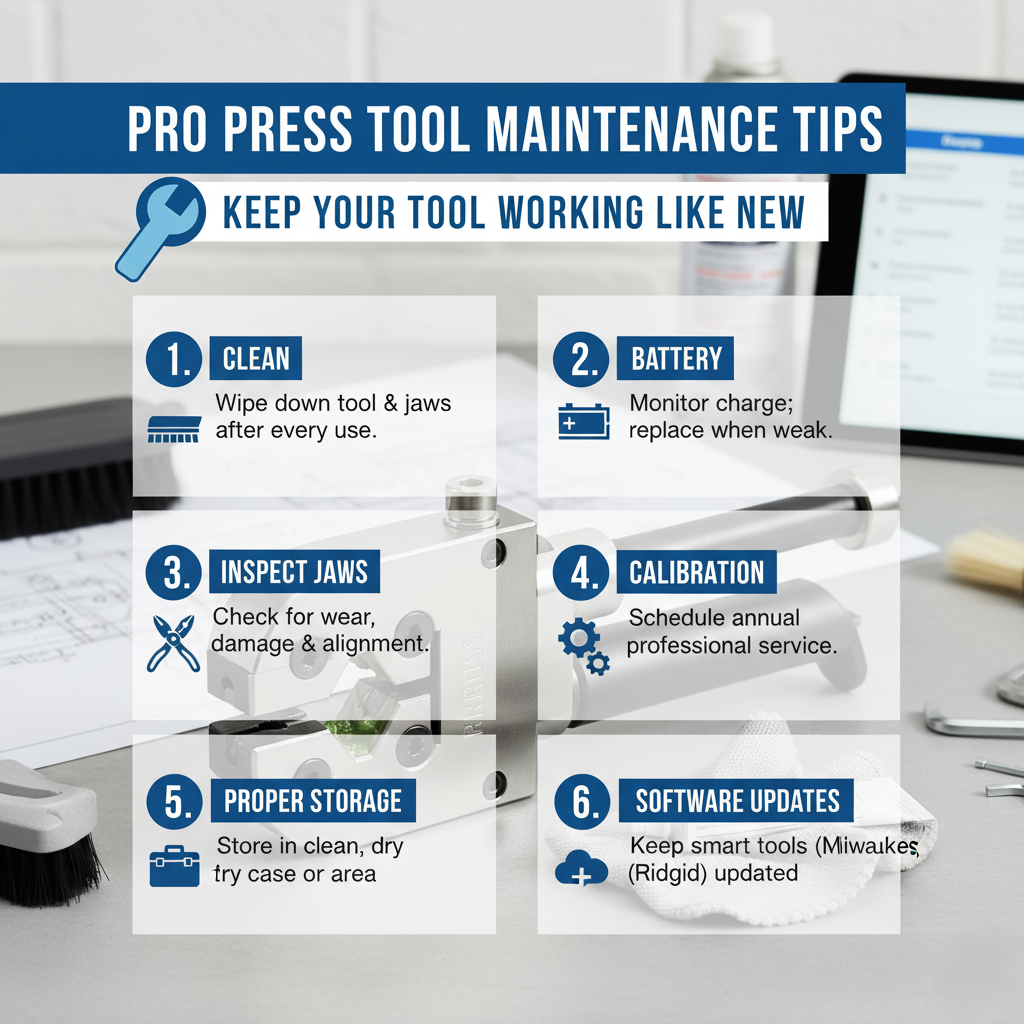

🧽 Step 1: Clean After Every Use

After finishing your job, spend 5-10 minutes cleaning the tool:

1. Wipe Down the Exterior

Use a clean, dry cloth to remove dirt, oil, and residue. Avoid water – instead, use a mild cleaner or rubbing alcohol.

2. Inspect the Jaws

Check for buildup, corrosion, or wear at the pressing surfaces.

Use a soft wire brush to gently remove any debris.

3. Lubricate Moving Parts

Apply a light machine oil (such as 3-in-1 or Ridgid’s recommended lubricant) to the pivot pins and jaw connections.

Do not over-lubricate – excess oil attracts dust.

🧩 Tip: Never use WD-40 on the hydraulic or battery components. It can damage seals and contacts.

⚡ Step 2: Check Battery Health

If you’re using a battery-powered Milwaukee or Ridgid press tool, battery maintenance is crucial.

- Always store batteries fully charged if not used for more than a week.

- Keep them away from heat and moisture.

- Clean the battery terminals with a dry cloth.

- Replace batteries showing signs of swelling, leakage, or short runtime.

🔋 Milwaukee M12 and M18 batteries perform best when charged between 40-80% during long-term storage.

🧩 Step 3: Inspect Jaws for Wear and Alignment

Press jaws are the most critical parts of your tool. Worn or misaligned jaws can cause uneven pressing or fitting failure.

Check for:

- Cracks or chips on the pressing surface

- Loose pivot pins

- Uneven closing gaps

If you notice any of these issues, replace the jaw immediately.

🧠 Tip: Mark your jaws with a press counter or usage log. After every ~10,000 presses, it’s smart to get them inspected.

🧰 Step 4: Schedule Regular Calibration

Calibration ensures your tool’s hydraulic or motorized system is pressing with the correct force.

Recommended Calibration Frequency:

| Brand | Interval | Service Option |

|---|---|---|

| Ridgid | Every 1 year or 32,000 cycles | Ridgid Authorized Service Center |

| Milwaukee | Every 1 year or 40,000 cycles | Milwaukee eService |

| Viega | Every 2 years | Certified service partners |

Skipping calibration can cause undetected leaks and warranty voids. Always send the tool to an authorized service center for recalibration.

🔧 For details, visit Ridgid Calibration Service or Milwaukee eService.

🧳 Step 5: Proper Storage

When not in use, store your pro press tool:

- In a clean, dry, and temperature-controlled environment

- Inside its original hard case or padded bag

- With the battery removed

- Away from direct sunlight or damp basements

🧩 Pro Tip: Add a small silica gel packet in the case to prevent rust or condensation.

⚙️ Step 6: Software Updates (Milwaukee & Ridgid Smart Tools)

Some newer models – like the Milwaukee M18 FORCE LOGIC Press Tool – include Bluetooth connectivity and firmware updates via the ONE-KEY app.

Keeping the software up to date can fix minor issues, improve press accuracy, and extend tool life.

You can find update guides here:

🧰 Quick Maintenance Checklist

| Task | Frequency |

|---|---|

| Wipe down after use | Every job |

| Inspect jaws | Weekly |

| Lubricate moving joints | Monthly |

| Calibrate tool | Every 12 months |

| Update firmware | As available |

| Replace batteries | Every 2-3 years |

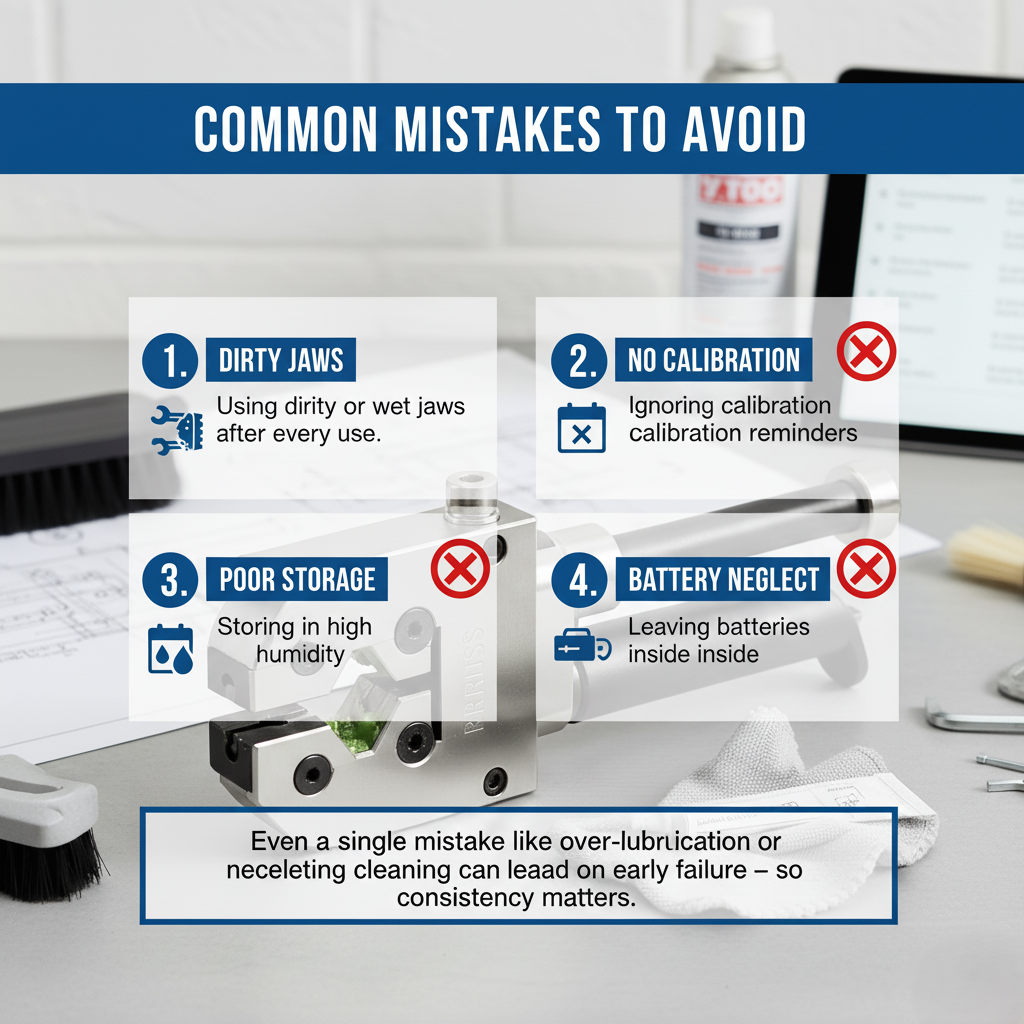

🧠 Common Mistakes to Avoid

- Using dirty or wet jaws

- Ignoring calibration reminders

- Storing the tool in high humidity

- Leaving batteries inside during storage

- Using non-approved lubricants

Even a single mistake like over-lubrication or neglecting cleaning can lead to early failure – so consistency matters.

🧩 Maintenance Costs

| Service | Typical Cost (USD) |

|---|---|

| Basic Cleaning Kit | $20-$40 |

| Calibration | $100-$200 |

| Jaw Replacement | $150-$250 |

| Battery Replacement | $80-$150 |

While that might sound like a lot, regular maintenance adds years to your tool’s life – easily saving hundreds in replacements.

FAQs

How often should I service my pro press tool?

Once a year or every 30,000-40,000 press cycles, depending on brand and usage frequency.

Can I calibrate my pro press tool myself?

No. Calibration must be done by an authorized service center using certified pressure gauges and diagnostic tools.

What happens if I don’t maintain my pro press tool?

You risk inconsistent presses, leaks, and voided warranty coverage. Performance and safety may also be compromised.

Can I use WD-40 or grease on the jaws?

Avoid both. Use only manufacturer-approved lubricants. WD-40 can break down seals and cause long-term damage.

How do I know when it’s time to replace the jaws?

If you notice uneven pressing, cracks, or a change in fit around the copper pipe, replace them immediately.

Can I use the same maintenance steps for PEX or stainless press tools?

Yes. The same cleaning and calibration principles apply across copper, PEX, and stainless systems.

Final Thoughts

Maintaining your pro press tool isn’t complicated – it just takes consistency.

A few minutes of cleaning and regular calibration can extend your tool’s life, save on costly repairs, and ensure your work stays leak-free.

If you’re unsure whether your tool needs service, check your press count or contact your local service center.

🧩 Also Read: Pro Press Tool Rental Guide – Where to Rent and How Much It Costs

📘 Or explore: How to Use a Pro Press Tool – Step-by-Step Guide